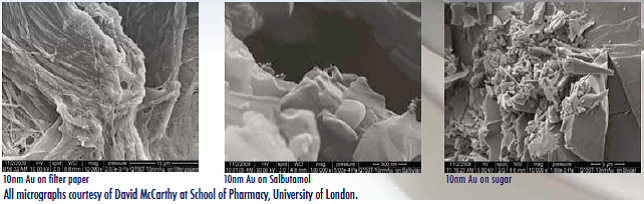

Ideal for SEM, high resolution FE-SEM and TEM applications

The Q150T is available in three formats: sputtering, carbon evaporation or both. Depending upon the selected configuration, the Q150T can be a top-of-the-range sputter coater for high resolution scanning electron microscopy (SEM), a carbon coater suitable for SEM and transmission electron microscopy (TEM), or both – in a single easy – to – use system. The ability of the Q150T to rapidly sputter a wide selection of oxidising and non – oxidising metals also makes it an ideal platform for many thin film applications.

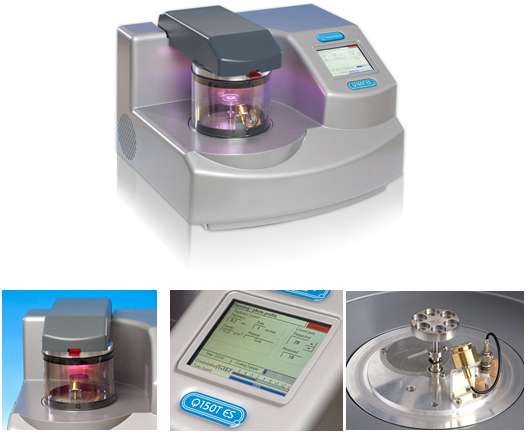

Moulded Case With Colour Touch Screen

The Q150T is presented in a custom moulded, one-piece case – allowing easy servicing access. The colour touch screen allows multiple users to input and store coating ‘recipes’. The case houses all the working components, including the efficient 70L/s air-cooled turbomolecular pump. Automatic bleed control ensures optimum vacuum conditions during sputtering.

The vacuum chamber has an internal diameter of 165mm/6” and comes with an integral implosion guard. The Q150T also includes ‘vacuum shutdown’, which enhances vacuum performance by allowing the chamber vacuum to be maintained when the system is not in use.A variable speed rotary specimen stage is fitted as standard, with other stages available as options – see Options and Accessories.

Sputter Coating, Carbon Coating Or Both

The three different formats of the Q150T each include a range of optional accessories:

*Q150T S- a high resolution sputter coater for oxidising and non-oxidising (noble) metals. A wide selection of sputtering targets is available, including iridium (Ir) and chromium (Cr) which are highly recommended for FE-SEM applications.

*Q150T E- a high vacuum carbon coater, ideal for the production of highly stable carbon films and surface replicas for transmission electron microscopy (TEM). The system uses economical, high purity 3.05mm Ø carbon rods.

*Q150T ES- a combined system with both sputtering and carbon coating. The deposition heads can be swapped in seconds and the intelligent system logic automatically recognises which head is in place and displays the appropriate operating settings.

Carbon coating – pulsed or ramped evaporation mode (Q150T ES and Q150T E)

Pulsed evaporation is suitable for most SEM carbon coating processes and for applications requiring enhanced control and reproducibly of thickness of deposition, for example for TEM carbon films.

Generally, this process requires the use of the optional extended-height chamber (see 10429). However, the shorter standard chamber may be used for coating thicknesses greater than 12nm. Additionally, if the short chamber is used, the FTM measurement may be inaccurate due to the close proximity of the high temperature carbon rods.

Pulsed Cleaning For Aluminium Sputtering

Aluminium (Al) can be difficult to coat due to its fast oxidising properties. Also, its oxidised layer is difficult to remove because it reduces the required target voltage to produce a sputter current of 150mA. This increases the time required to clean the target.

However, the Q150T ES and Q150T S have special profiles for aluminium (Al) that reduce the oxide removal time and prevent excessive pre-sputtering of the already clean target.

The Q150T is available in three formats:

Q150T S - a high resolution sputter coater, suitable for oxidising and non-oxidising metals

Q150T E- a high vacuum carbon coater for SEM and TEM applications

Q150T ES- a high resolution sputter and high vacuum coater

Accessories:

• Extended height chamber for tall specimens.

• Film thickness monitor (FTM).

• Full range vacuum gauge for low and high vacuum

measurement (a Pirani gauge is fitted as standard).